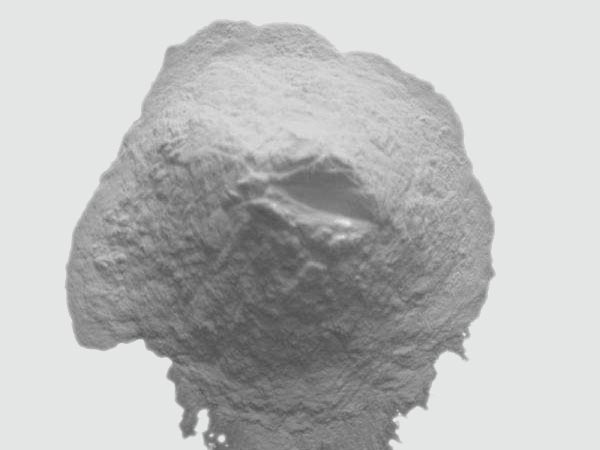

Ceramic Foundry Sand

Ceramic Foundry Sand, technically named as “Fused Ceramic Sand for Foundry”, also named as ceramite, is good spherical grain shape which is made from calcined bauxite. Its main content is aluminum oxide, and it is processed by melting, blowing, sieving and blending. Ceramic sand, has much better properties than that of silica sand to gain a better performance in foundry.